Sodium Sulfate

Product Details

Specifications provided

White powder (Content ≥99% )

(Scope of application reference ‘product usage’)

Monoclinic crystal system, short columnar crystal, compact mass or crust, colorless transparent, sometimes with light yellow or green, easily soluble in water. A white, odorless, salty, bitter crystal or powder with hygroscopic properties. The shape is colorless, transparent, large crystals or small granular crystals. Sodium sulfate is a strong acid and alkali salt containing oxic acid.

EVERBRIGHT® ‘ll also provide customized :content/whiteness/particlesize/PHvalue/color/packagingstyle/ packaging specifications and other specific products that are more suitable for your use conditions , and provide free samples.

Product Parameter

7757-82-6

231-820-9

142.042

Sulphate

2680 kg/m³

soluble in water

1404 ℃

884 ℃

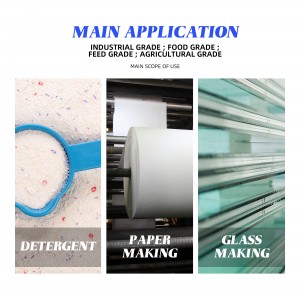

Product Usage

Dyeing additive

1.pH regulator: Sodium sulfate can adjust the pH value between dyes and fibers to help dye molecules react better with fibers and improve dyeing effect.

2. Ion buffer: Sodium sulfate can be used as an ion buffer to stabilize the ion concentration of the solution during the dyeing process to prevent the ions of other components from participating in the reaction and affecting the dyeing effect.

3. Solvent and stabilizer: Sodium sulfate can be used as a solvent and stabilizer to help the dye dissolve in water, and maintain the stability of the dye, avoid dye decomposition or failure.

4. Ion neutralizer: dye molecules usually have charged groups, and sodium sulfate can be used as an ion neutralizer to react with the cation part of the dye molecule to stabilize the structure of the dye molecule and improve the dyeing effect.

Glass industry

As a clarifying agent to remove air bubbles in glass liquid and to provide sodium ions required for glass production.

papermaking

A cooking agent used in the paper industry to make kraft pulp.

Detergent additive

(1) decontamination effect. Sodium sulfate can reduce the surface tension of the solution and the critical concentration of micelles, and increase the adsorption rate and adsorption capacity of the detergent on the fiber, increase the solubility of the solute in the surfactant, and thus improve the decontamination effect of the detergent.

(2) The role of washing powder molding and preventing caking. As sodium sulfate is an electrolyte, the colloid is condensed to shake, so that the specific gravity of the slurry increases, the fluidity becomes better, which helps to shape the washing powder, and more sodium sulfate also has a certain effect on preventing the formation of light powder and fine powder. Sodium sulfate mixed with washing powder has the effect of preventing the agglomeration of washing powder. In synthetic laundry detergent, the amount of sodium sulfate is generally more than 25%, and there are as high as 45-50%. In the soft areas of water quality, it is appropriate to increase the amount of glauber nitrate appropriately.