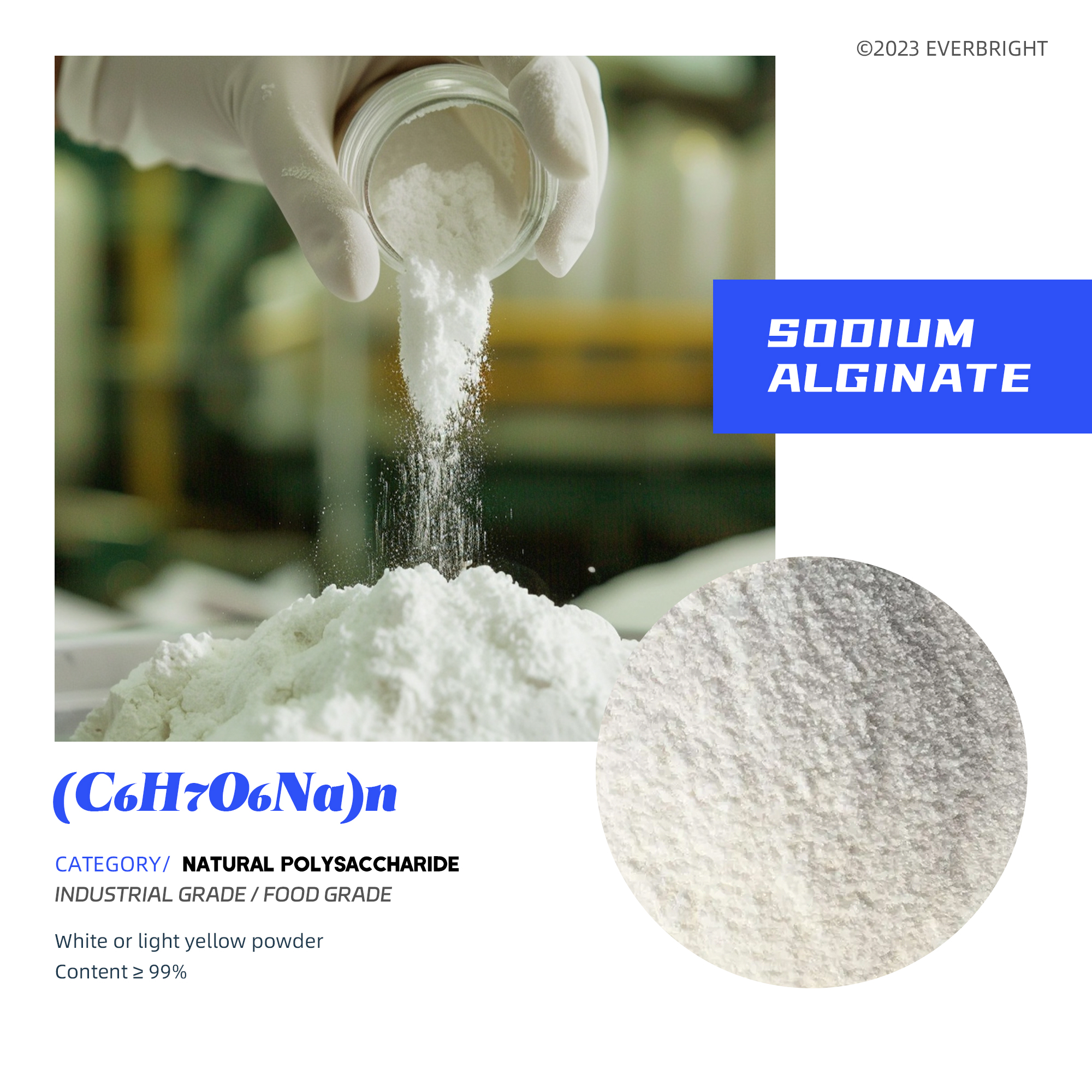

Sodium Alginate

Product Details

Specifications provided

White or light yellow powder

Content ≥ 99%

(Scope of application reference ‘product usage’)

Sodium alginate is white or light yellow powder, almost odorless and tasteless. Sodium alginate soluble in water, insoluble in ethanol, ether, chloroform and other organic solvents. Dissolves in water to form a viscous liquid, and the pH of 1% aqueous solution is 6-8. When pH=6-9, the viscosity is stable, and when heated to more than 80℃, the viscosity decreases. Sodium alginate is non-toxic, LD50>5000mg/kg. Effect of chelating agent on the properties of sodium alginate solution Chelating agent can complex divalent ions in the system, so that sodium alginate can be stable in the system.

EVERBRIGHT® ‘ll also provide customized :content/whiteness/particlesize/PHvalue/color/packagingstyle/ packaging specifications and other specific products that are more suitable for your use conditions , and provide free samples.

Product Parameter

9005-38-3

231-545-4

398.31668

Natural polysaccharide

1.59 g/cm³

Soluble in water

760 mmHg

119°C

Product Usage

Food addition

Sodium alginate is used to replace starch and gelatin as a stabilizer for ice cream, which can control the formation of ice crystals, improve the taste of ice cream, and stabilize mixed drinks such as sugar water sorbet, ice sherbet, and frozen milk. Many dairy products, such as refined cheese, whipped cream, and dry cheese, utilize sodium alginate's stabilizing action to prevent the food from sticking to the package, and can be used as a decorative coating to stabilize it and prevent cracking of the frosting crust.

Sodium alginate is used as a thickening agent for salad (a kind of salad) sauce, pudding (a kind of dessert) canned products to improve the stability of the product and reduce liquid leakage.

Can be made into a variety of gel food, maintain a good colloidal form, no seepage or shrinkage, suitable for frozen food and artificial imitation food. It can also be used to cover fruits, meat, poultry and aquatic products as a protective layer, which is not in direct contact with the air and extends the storage time. It can also be used as a self-coagulating agent for bread icing, filling filler, coating layer for snacks, canned food and so on. The original form can be maintained in high temperature, freezing and acidic media.

It can also be made of elastic, non-stick, transparent crystal jelly instead of gelatine.

Printing and dyeing industry

Sodium alginate is used as reactive dye paste in printing and dyeing industry, which is superior to grain starch and other pastes. The printed textile pattern is bright, the lines are clear, the color amount is high, the color is uniform, and the permeability and plasticity are good. Seaweed gum is the best paste in modern printing and dyeing industry, and has been widely used in the printing of cotton, wool, silk, nylon and other fabrics, especially for the preparation of dyeing printing paste.

Pharmaceuticals industry

The PS type gastrointestinal double-contrast barium sulfate preparation made of alginate sulfate dispersant has the characteristics of low viscosity, fine particle size, good wall adhesion and stable performance. PSS is a kind of sodium diester of alginic acid, which has the function of anticoagulation, lowering blood lipid and reducing blood viscosity.

Using seaweed gum instead of rubber and gypsum as dental impression material is not only cheap, easy to operate, but also more accurate to print teeth.

Seaweed gum can also be made of various dosage forms of hemostatic agents, including hemostatic sponge, hemostatic gauze, hemostatic film, scalded gauze, spray hemostatic agent, etc.